The Creality Ender 3 Pro is a popular and affordable FDM (fused deposition modeling, also called fused filament fabrication, or FFF) 3D printer that has gained a strong following among hobbyists and makers. Known for its reliability, ease of use, and upgrade-ability, the Ender 3 Pro is a great choice for both beginners and experienced users.

My best man gifted my wife and me (mostly me) an Ender 3 Pro for our wedding. So far, most of the printing I've done has only served to improve the printer... I've made several upgrades and modifications to enhance its performance and usability.

Upgrades

Extruder

One thing almost every Ender owner will end up doing is replacing the stock, plastic extruder mechanism with a more robust aluminum model (such as this ). A design flaw with the original often leads to the plastic snapping with some continuous usage— causing under-extrusion or preventing filament from traveling through the Bowden tube altogether.

This was one of the first upgrades I made to the printer, and it significantly improved print reliability.

Printable Upgrades

There are many printable upgrades available for the Ender 3 Pro that can enhance its performance and usability. Some of the additions I've found particularly useful:

-

Cable Chains

Cable chains help manage and protect the printer's wiring— reducing wear and tear, and keeping wires organized during operation. -

Filament Guides

A filament guide helps ensure smooth feeding of the filament into the extruder, reducing the risk of jams and tangles. -

Spool Holder

An upgraded spool holder with smooth bearings can accommodate larger spools and provide better support, reducing strain on the filament during printing. -

Camera Mount

A camera mount allows for easy installation of a webcam or Raspberry Pi camera module, enabling remote monitoring and time-lapse recording of prints.

Control Software

Klipper Firmware

One of the most significant upgrades I've made to my Ender 3 Pro is installing Klipper firmware . Klipper is an open-source firmware that runs on a host computer (like a Raspberry Pi) and communicates with the printer's microcontroller (MCU).

This offers several advantages over traditional firmware, including:

- Improved print quality and speed

- Advanced features like pressure advance and input shaping

- Easier configuration and updates via a web interface

- Support for multiple MCUs and complex printer setups

To install Klipper, I followed the official installation guide

. I used the printer.cfg

specific to my model after opening the controller enclosure and inspecting the MCU on the printer's mainboard. My model uses the STM32F103 chip with a v4.2.2 controller.

You'll need to format a microSD card with the Klipper firmware binary and insert it into the printer's mainboard. When you power on the printer, it will flash the new firmware automatically. You can then remove the microSD card and finish the host software setup on your Raspberry Pi.

On my first homing after flashing the Klipper firmware, the hotend gantry was overrunning the available track and causing the belt to skip and grind as it tried to push beyond the available space. To prevent this, I needed to update the default printer.cfg from Moonsail to provide a lower (-1cm) limit for X, Y, and Z travel. Here's the diff:

# This file contains pin mappings for the stock 2020 Creality Ender 3

# Pro with the 32-bit Creality 4.2.2 board. To use this config, during

# "make menuconfig" select the STM32F103 with a "28KiB bootloader" and

# serial (on USART1 PA10/PA9) communication.

# It should be noted that newer variations of this printer shipping in

# 2022 may have GD32F103 chips installed and not STM32F103. You may

# have to inspect the mainboard to ascertain which one you have. If it

# is the GD32F103 then please select Disable SWD at startup in the

# "make menuconfig" along with the same settings for STM32F103.

# If you prefer a direct serial connection, in "make menuconfig"

# select "Enable extra low-level configuration options" and select

# serial (on USART3 PB11/PB10), which is broken out on the 10 pin IDC

# cable used for the LCD module as follows:

# 3: Tx, 4: Rx, 9: GND, 10: VCC

# Flash this firmware by copying "out/klipper.bin" to a SD card and

# turning on the printer with the card inserted. The firmware

# filename must end in ".bin" and must not match the last filename

# that was flashed.

# See docs/Config_Reference.md for a description of parameters.

[stepper_x]

step_pin: PC2

dir_pin: PB9

enable_pin: !PC3

microsteps: 16

rotation_distance: 40

endstop_pin: ^PA5

position_endstop: 0

- position_max: 235

+ position_max: 225

homing_speed: 50

[stepper_y]

step_pin: PB8

dir_pin: PB7

enable_pin: !PC3

microsteps: 16

rotation_distance: 40

endstop_pin: ^PA6

position_endstop: 0

- position_max: 225

+ position_max: 225

homing_speed: 50

[stepper_z]

step_pin: PB6

dir_pin: !PB5

enable_pin: !PC3

microsteps: 16

rotation_distance: 8

endstop_pin: ^PA7

position_endstop: 0.0

- position_max: 250

+ position_max: 240

[extruder]

max_extrude_only_distance: 100.0

step_pin: PB4

dir_pin: PB3

enable_pin: !PC3

microsteps: 16

rotation_distance: 34.406

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PA1

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC5

control: pid

# tuned for stock hardware with 200 degree Celsius target

pid_Kp: 21.527

pid_Ki: 1.063

pid_Kd: 108.982

min_temp: 0

max_temp: 250

[heater_bed]

heater_pin: PA2

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC4

control: pid

# tuned for stock hardware with 50 degree Celsius target

pid_Kp: 54.027

pid_Ki: 0.770

pid_Kd: 948.182

min_temp: 0

max_temp: 130

[fan]

pin: PA0

[include mainsail.cfg]

+ # Include moonraker-timelapse config

+ [include timelapse.cfg]

[mcu]

serial: /dev/serial/by-id/usb-1a86_USB_Serial-if00-port0

restart_method: command

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

# Pin mappings for BL_T port

#[bltouch]

#sensor_pin: ^PB1

#control_pin: PB0

[display]

lcd_type: st7920

cs_pin: PB12

sclk_pin: PB13

sid_pin: PB15

encoder_pins: ^PB14, ^PB10

click_pin: ^!PB2

Mainsail

I'm using Mainsail as the Klipper web interface for managing the printer. It's virtually the same as Fluidd — another popular Klipper web interface.

Mainsail provides a very lightweight web interface for Klipper that makes printer control and monitoring simple and straightforward. It's also mobile-responsive, so I can check prints and manipulate the printer from my smartphone. It offers features like:

- Real-time temperature monitoring

- Motor control

- Print job management

- G-code viewer

- System status and logs

- Camera integration with the Crowsnest plugin

OctoPrint

OctoPrint is another popular web interface for 3D printers, and it's what I used before flashing the Klipper firmware. Mainsail is specifically designed for Klipper and offers a more streamlined experience. However, OctoPrint will also work with Klipper, and it provides similar functionality to Mainsail.

OctoPi

One of my favorite ways to run OctoPrint is using OctoPi , a pre-configured Raspberry Pi image that includes OctoPrint and all necessary dependencies. This makes it easy to set up a dedicated print server for the Ender 3 Pro— letting you manage prints remotely and monitor the printer in the browser over Wi-Fi.

Tips and Tricks

Here are a few tips and tricks I've learned while using the Ender 3 Pro:

-

Bed Leveling

Regularly check and adjust the bed leveling to ensure optimal print adhesion and quality. I use a piece of paper to gauge the distance between the nozzle and the bed at various points. The paper should just barely slide with slight resistance. -

Nozzle Cleaning

Keep the nozzle clean to prevent clogs and ensure consistent extrusion. I use a brass wire brush to gently clean the nozzle after prints, and occasionally perform a cold pull to remove any residual filament. Stock up on additional nozzles for when you get a clog that can't be easily resolved. -

Smart Plug

I use a smart plug to control the power to my Ender 3 Pro remotely. This allows me to turn the printer on and off from my phone and schedule print jobs without needing to be physically next to the printer. -

Timelapse

If you're using a camera with Mainsail, you can set up timelapse recordings of your prints. This is a great way to document your printing process and share your creations with others. Follow instructions to clone the moonraker-timelapse repo and build the plugin. You'll need to add the following lines to yourmoonraker.conffile:

[timelapse]

output_path: ~/printer_data/timelapse/

frame_path: /tmp/timelapse/printerYou can also allow the Moonraker update manager to handle updates for the timelapse plugin by adding this section to your moonraker.conf:

[update_manager timelapse]

type: git_repo

primary_branch: main

path: ~/moonraker-timelapse

origin: https://github.com/mainsail-crew/moonraker-timelapse.git

managed_services: klipper moonraker

Micro SD Backup

If your Klipper host (I'm using a Raspberry Pi) fails to finish the boot sequence— revealing the dreaded blinking cursor/black screen of death instead of starting up the Moonsail/Fluidd interface— you might have a corrupt SD card. Every Raspberry Pi enthusiast has faced the awful reality of a bad micro SD card. It's a legitimate problem that can destroy your morale and make 3D printing much less fun.

Instead of repeatedly flashing Raspberry Pi OS, you can mitigate this risk by periodically backing up the contents to another storage device. I have a 32GB card in the Pi, so I used another 32GB card to create an identical copy using balenaEtcher . In this way, if the primary card fails, I can quickly swap in the other card and get back to printing.

Insert the source card into your computer, launch balenaEtcher, and select "Clone Drive" from the main menu. You can tell which is which by plugging both in then unplugging one and clocking which disappeared from the clone menu. You'll need to first format the backup as FAT32 before cloning. Choose the source and target, then start the cloning process. Once complete, label the backup card with the date so you know when it was created.

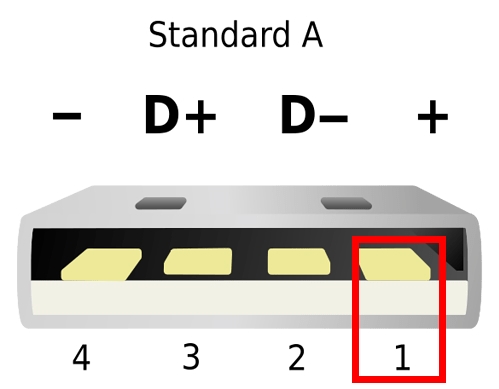

Raspberry Pi USB Power Trick

If you're using a Raspberry Pi with Klipper or OctoPrint to control your Ender 3, you might notice that the USB connection can power the Ender's TFT screen— even when the main printer PSU is shut off.

To avoid this, I took a small strip of painter's tape and covered the 5V pin (the rightmost pin when looking straight into the male USB plug). This prevents back-powering the printer's screen when the Pi is powered on independently which could potentially cause screen damage over time.