3D printing is getting better and better all the time. When I was in undergrad for architecture, I had access to a powder-based printer in the fab lab that would precisely deposit micro droplets of a resin binder— gradually fusing layers of powder into a solid object. In my experience, this method of printing produced rather brittle prints and the resolution was mediocre compared to most modern printers.

There was also a professor, Sasa Zivkovic, who ran a studio that produced a large-format, pellet-based FDM printer while I was at school. The CNC (computer numerical control) gantry system was even later repurposed for a student's PhD on concrete printing. This allowed for very large prints, but the resolution was limited by the nozzle size and the precision of the gantry system.

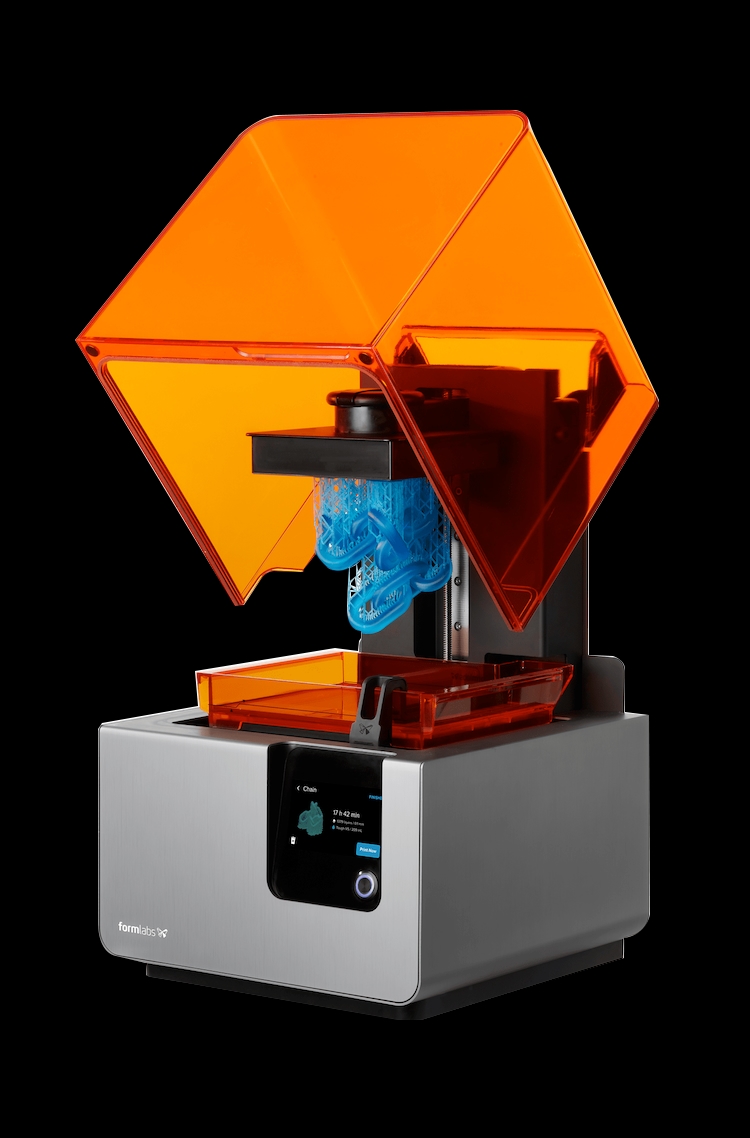

Resin (SLA) Printing

Interning at several experimental marketing shops exposed me to a variety of digital fabrication tools as well. Many of these shops did full service design-build in house. The first time I got to print on a FormLabs Form 2 resin-based SLA printer, I was blown away by the material engineering and the quality of the cured parts.

SLA prints have much, much higher resolution— a high-resolution screen that emits light in the UV wavelength will cure the resin against a flat translucent pane at each layer. So, contrary to FDM, the print is lifted from the print surface.

Even compared to modern FDM (fused deposition) printers with fine nozzle gauges, SLA often excels in speed and quality. However, the resins are toxic and messy to work with. Post-processing is required to fully cure the prints, and support structures must be carefully removed.

Filament (FDM) Printing

FDM printing has come a long way, especially in recent years. These printers are generally more affordable than resin printers, and the materials are less toxic and easier to work with. The most common filaments are PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene). PLA is biodegradable and easier to print with, while ABS is more durable and heat-resistant.

Slicing Software

There are several popular slicing software options available for preparing 3D models for printing. Some of the most widely used include:

- Cura

A free and open-source slicer developed by Ultimaker. It offers a user-friendly interface and a wide range of customization options. - PrusaSlicer

Developed by Prusa Research, this slicer is optimized for Prusa printers but works well with other models too. - Simplify3D

A paid slicer that offers advanced features and fine-tuning options for experienced users. - OrcaSlicer

A newer slicer that has gained popularity for its speed and efficiency.

I've primarily used Cura for my prints, as it strikes a good balance between ease of use and advanced features.

Benchmarking

One of the most popular models for benchmarking 3D printers is the Benchy . This small boat model is designed to test various aspects of a printer's performance, including overhangs, bridging, and surface finish. Printing a Benchy can help identify any issues with your printer's calibration and settings.

If you're like me and have a small toddler, it can also double as a fun toy!